El proceso completo de fabricación de una caja de EVA termoformada se puede dividir en ocho etapas: Preparación del material EVA → Selección de materiales de superficie → Corte de EVA → Procesamiento de logotipo o patrón en cajas → Preprensado → Termoformado → Enfriamiento y recorte → Costura, luego inspección y empaque, se completa una versátil caja de almacenamiento de EVA.

Los parámetros clave del proceso se concentran en la etapa de termoformado.

A continuación se explica cada paso en orden, junto con los rangos de control más utilizados, lo que facilita que las marcas puedan hacer referencia directa al diseñar y personalizar estuches para lápices o cajas de almacenamiento de EVA.

Seleccione EVA con la dureza adecuada: dependiendo del espesor de pared requerido y de la firmeza de la caja de lápices, elija láminas de espuma EVA con una densidad de 200–300 kg/m³ y una dureza de 55–80 grados.

Para estuches de EVA pequeños y livianos (como estuches para gafas o para iPod), se recomienda EVA con una dureza de 65 grados.

Para cajas de herramientas o cajas de almacenamiento de productos electrónicos, se recomienda una dureza de 75 grados o más para garantizar que la caja mantenga su forma y no se deforme fácilmente.

Tras elegir las láminas de EVA con la dureza adecuada, el siguiente paso es seleccionar el tejido de superficie que se laminará sobre ellas. La opción más común es el tejido de punto de poliéster, que presenta una superficie lisa, excelente elasticidad y un precio relativamente bajo, lo que lo convierte en la opción preferida para la mayoría de las fundas de EVA estándar.

Además, los clientes pueden seleccionar materiales personalizados según las necesidades de su producto o el posicionamiento de su marca. Por ejemplo, el cuero sintético laminado con EVA se utiliza a menudo para fabricar artículos como estuches para lápices y organizadores de EVA.

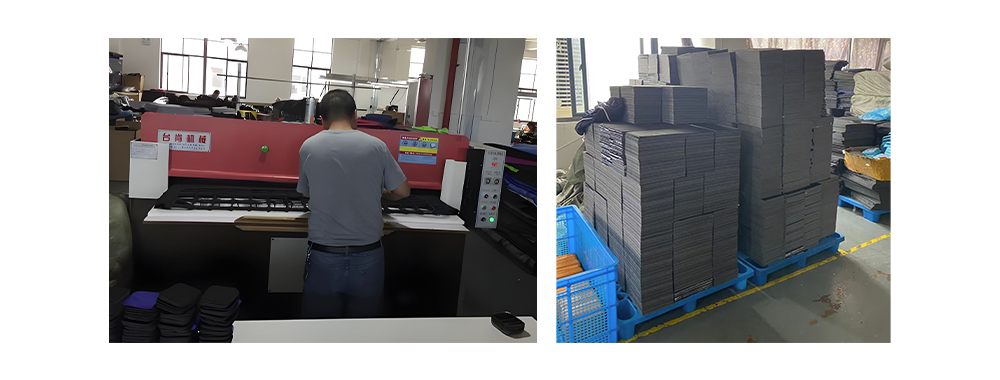

Coloque la lámina de EVA laminada plana y córtela en piezas individuales. El tamaño del corte debe ser aproximadamente 20 mm mayor que el perímetro del molde. Este margen adicional garantiza que los materiales con diferentes tasas de contracción tengan suficiente espacio para estirarse y, además, evita la escasez de material durante el proceso de termoformado.

4.1. Los patrones decorativos o logotipos de la caja de EVA pueden imprimirse mediante serigrafía, transferencia térmica o sublimación. Estas impresiones no se verán afectadas por el proceso de termoformado posterior.

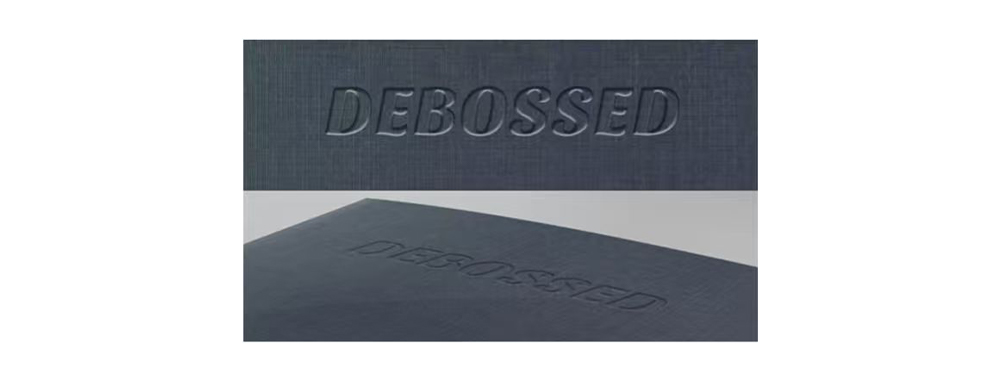

4.2. Logotipo grabado en bajorrelieve: El patrón o logotipo también puede grabarse directamente en el molde de termoformado, lo que permite su formación en un solo paso. En este caso, no se requiere ninguna decoración adicional del logotipo como se indicó anteriormente.

Primero, precaliente el material en un horno a 60–80 °C durante 30–60 segundos, esto ayuda a acortar el ciclo de termoformado posterior y mejora la planitud de la superficie.

A continuación, coloque la lámina cortada en el molde de prensado en frío y aplique una ligera presión de 2 a 4 MPa durante 5 a 10 segundos. Esto permite que la lámina se adapte inicialmente al molde, reduciendo el deslizamiento o desplazamiento durante el termoformado y minimizando las arrugas.

Este es el proceso principal en la producción de una caja de EVA termoformada. Mediante una termoformadora de cuatro columnas con placas calentadas eléctricamente y temperaturas de molde superior e inferior controladas independientemente, se logra la forma final de la caja.

~45 s para un espesor de pared de 3 mm

~60 s para un espesor de pared de 4 mm

Por cada 1 mm adicional de espesor de EVA, aumente el tiempo de termoformado entre 10 y 15 segundos.

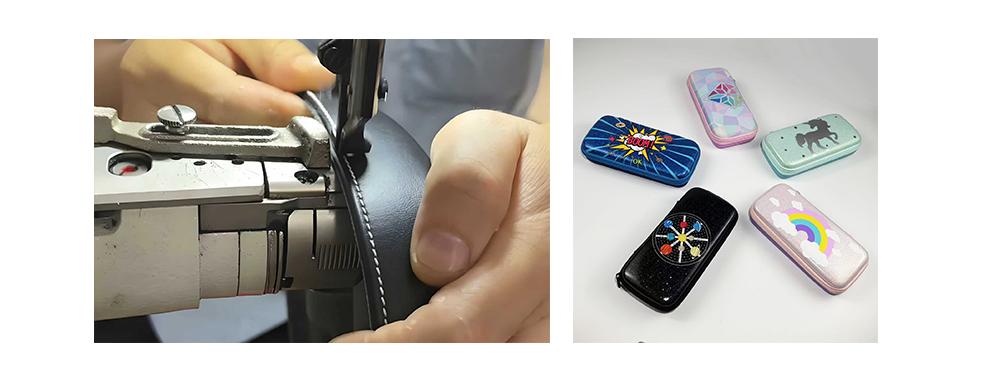

Cosa la cubierta o la base de EVA termoformada junto con la cinta de cierre y otros componentes como asas de transporte de cincha, agregue herrajes como remaches o parches con el logotipo mediante una remachadora neumática, con esto el proceso de ensamblaje de una caja de lápices o una caja de almacenamiento está casi terminado.

Por último, pero no por ello menos importante, la inspección y la emisión de billetes antes del embalaje en cajas maestras.

Por cada aumento de 5 °C en la temperatura, la presión puede reducirse en 1 MPa, y viceversa.

Los moldes de cavidad profunda requieren ranuras de ventilación de 0,05 a 0,1 mm para evitar bordes quemados y reducir problemas como burbujas en la superficie o delaminación localizada de telas laminadas durante el formado.

Pruebe la duración óptima del enfriamiento antes de la producción en masa. Reducir el tiempo de enfriamiento innecesario puede mejorar significativamente la productividad.

Durante días de lluvia o humedad continua, se recomienda presecar las láminas a unos 50 °C durante aproximadamente 3 horas antes de la producción.

Registre la temperatura, la presión y el tiempo de enfriamiento. Detenga la máquina inmediatamente y ajuste el molde si detecta desviaciones.

Siguiendo los procedimientos y parámetros anteriores, una caja de EVA con un espesor de pared estándar de 5 mm puede lograr una producción diaria de 1200 piezas por máquina, con una tasa de rendimiento de ≥98%.

| Autor | ||||||

|

Derechos de autor

@2024 Synberry Bag & Package Products Co.,Ltd Reservados todos los derechos

.

RED SOPORTADA

RED SOPORTADA